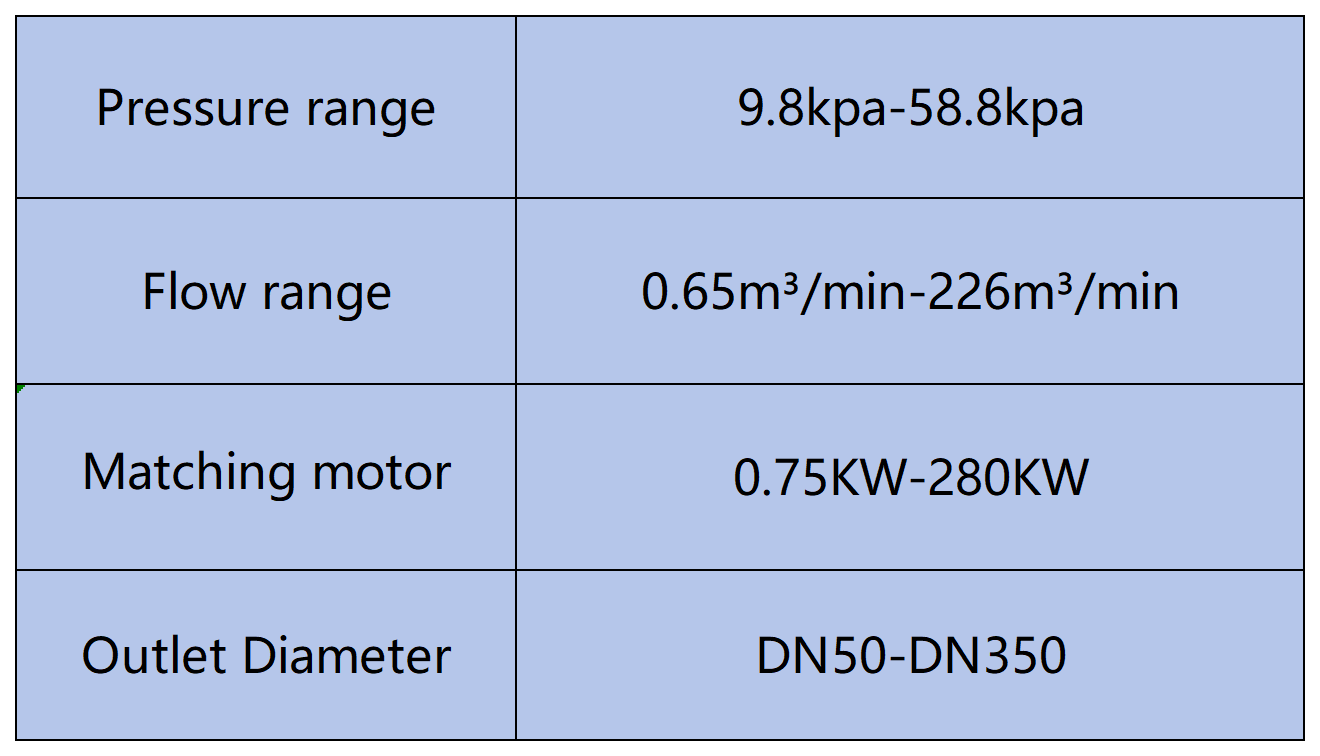

Flow rate:0.78-198.1m³/min

Pressure:58.8-98kpa

Motor power:0.55-400kw

1.low noise. The air inlet and exhaust port of the fan adopts spiral shape, so that the air inlet and exhaust process cuts in the direction of the spiral line in a sequential manner, which avoids the pulsating noise and vibration that broke out instantly during the exhaust of the old-style fan exhaust fan.

2.The Roots blower for biogas transportation adopts Yin-resistant composite silencer, which further reduces the noise.

3.Adiabatic efficiency and volumetric efficiency are high, thus saving energy. The rotor of Roots blower adopts advanced composite curve, the meshing is more reasonable, and the volumetric efficiency is enlarged.

4.Small vibration. Although the rotor has been precision machined, has become a balanced state. But still using high-precision dynamic balancing equipment for balancing. Therefore, there is almost no vibration in the operation of the blower.

5.the use of high-precision, high hardness synchronous gear, not only to extend the life of the blower, but also effectively reduce the noise.

6.This series of blower adopts bearings imported from Japan or Germany and rubber belts imported from Korea or Taiwan, which makes the product quality more reliable.

7.The output air is clean and does not contain any oil or dust. The sealing structure of the Roots blower is reasonable, so that the oil can not enter the casing, thus the air is clean.

The biogas conveying blower is mainly used in the pharmaceutical, chemical, coal mining, glass industry waste disposal and other industries. It is designed for the characteristics of corrosive media and complex components in similar industries. It plays an important role in the ventilation and exhaust of special gas transportation such as coal gas, biogas, natural gas and so on.