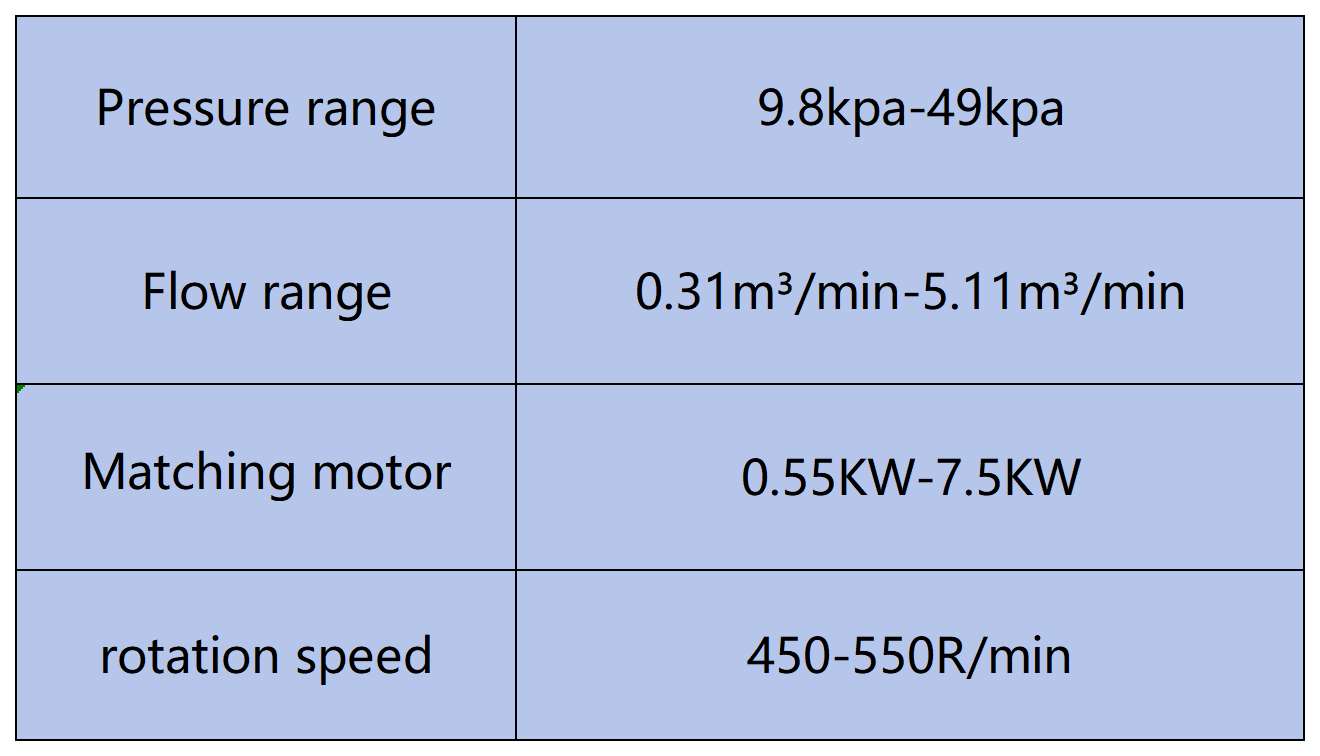

Flow rate range:0.27-5.11m3/min

Boost pressure:9.8-49kpa

Motor power:0.55kw-7.5kw

It mainly consists of the following six parts: motor, air filter, blower unit, air chamber, base (cum oil tank), and drip nozzle.

The blower operates eccentrically by the rotor offset in the cylinder and makes the volume change between the blades in the rotor groove to inhale, compress and exhale the air.

During operation, the pressure difference of the blower is utilized to automatically send lubricant to the drip nozzle, which drips into the cylinder to reduce friction and noise, and at the same time keeps the gas in the cylinder from flowing back.

Rotary Roots blower relies on the eccentric rotation of the rotor offset in the cylinder, and makes the volume change between the blades in the rotor groove to inhale, compress and spit out the air.

During operation, the pressure difference of the blower is utilized to automatically send lubricating oil to the drip nozzle, which drips into the cylinder to reduce friction and noise, and at the same time keeps the gas in the cylinder from flowing back.

1.Water Treatment Blast Aeration

2. Hospitals, hotels, laboratories, sewage mixing aeration

3. Gas supply for plastic welding and food packaging blowing.

4. Vacuum paper feeding in printing industry

5. Electroplating tank, industrial wastewater mixing aeration

6. Spraying of burners, glass industry and others.