Company News

Pneumatic conveying silo pumps

2024-08-01 10:41:52

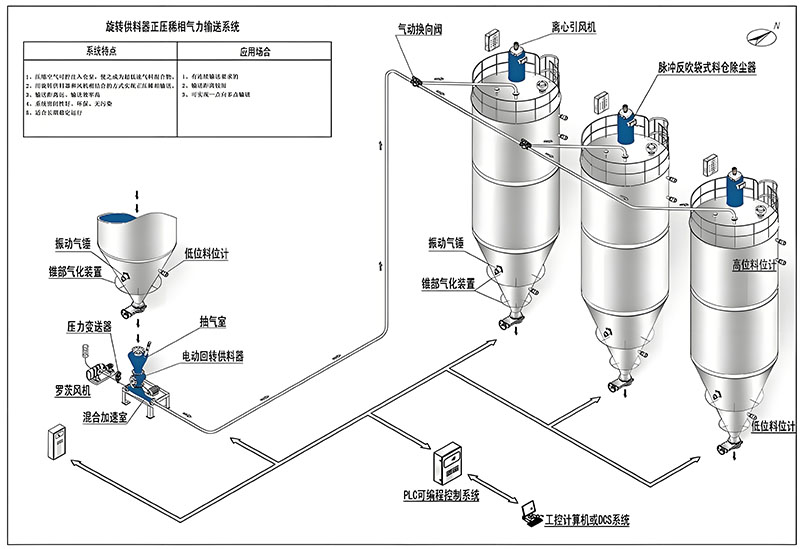

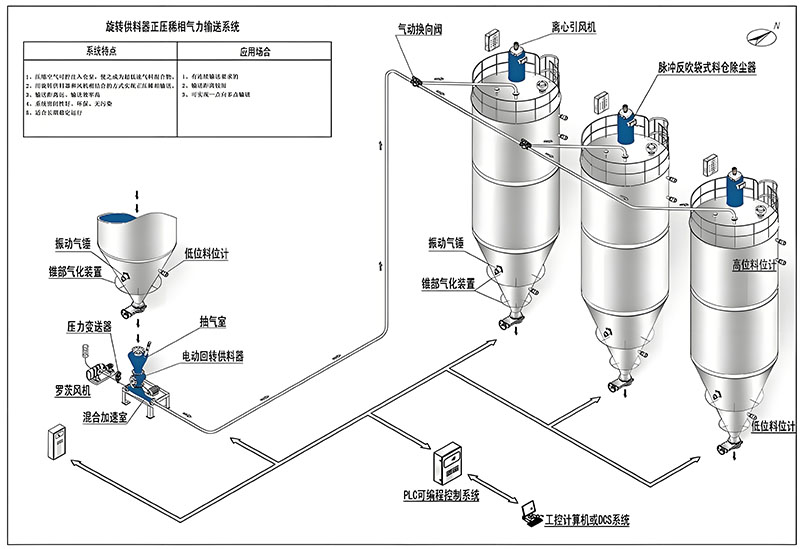

Brief introduction of the product

Silo pneumatic conveying pump adopts positive pressure pneumatic conveying method to convey powdery materials, which is widely used in the conveying of fly ash, cement, cement raw material, mineral powder and other materials in power plants. The conveying pipeline can be flexibly arranged according to the terrain conditions to achieve centralised, decentralised, large height and long distance conveying, the conveying process is not affected by the natural conditions, which ensures that the materials are not damp and are environmentally friendly and pollution-free. This equipment adopts PLC control system, which can be controlled automatically or manually, and it is proved through long-term practical operation: this equipment has stable performance, reliable quality, conveying without dust pollution, and it is the ideal pneumatic conveying equipment.

Silo pneumatic conveying pump adopts positive pressure pneumatic conveying method to convey powdery materials, which is widely used in the conveying of fly ash, cement, cement raw material, mineral powder and other materials in power plants. The conveying pipeline can be flexibly arranged according to the terrain conditions to achieve centralised, decentralised, large height and long-distance conveying, and the conveying process is not affected by the natural conditions, which ensures that the materials are not damp and are environmentally friendly and pollution-free. This equipment adopts PLC control system, can be automatically or manually controlled, through long-term practice and operation has been proved: the equipment has stable performance, reliable quality, conveying no dust pollution, is the ideal pneumatic conveying equipment.

1. No pipe blockage

Pneumatic conveying silo pump can basically adapt to any powder material pneumatic conveying, the installation of pneumatic conveying silo pump system basically does not occur plugging, the reliability is very high. Even, want to artificially plug the pipe is a very difficult thing!

2.Long-distance pneumatic conveying

Silo pump can achieve the ideal long-distance pneumatic conveying. At present, in the domestic case, the conveying distance of more than 2,000 metres and stable operation of the only concentrated phase pneumatic conveying system.

3. Low energy consumption

There are only three processes in the conveying process of warehouse pump, feeding, pressurised conveying, omitting the step of pipeline blowing, the warehouse pump can achieve full-pipe thick-phase pneumatic conveying, with low flow rate, and it can stop conveying when there is no ash, which will not affect the next conveying process, and it will not block the pipe.

4. Low wear and tear

Because of the low flow rate of the warehouse pump, wear and tear is actually proportional to the flow rate, warehouse pump pneumatic conveying flow rate is generally not more than 5m/s, a lot of customers do not understand the general number of people conveyor pressure will increase wear, in fact, the pressure of the pneumatic conveying and wear and tear is not related. The higher the conveying speed of the material, the more wear and tear.

5. High efficiency

The introduction of environmental protection also do thin-phase pneumatic conveying, but we also have to admit that for the warehouse pump, the same conveying project, warehouse pump conveying capacity than thin-phase pneumatic conveying can be increased up to twice as much!

6. Specific gravity

Concentrated-phase pneumatic conveying of silo pump is more adaptable, and can convey almost any powder.

7. Simple configuration

The configuration of silo pump is very simple, modular components can save a lot of cost.

Henan Jiye Chang Industry Co.

2024-08-01 10:41:52

2024-08-01 10:41:52